| Details description |

|---|

|

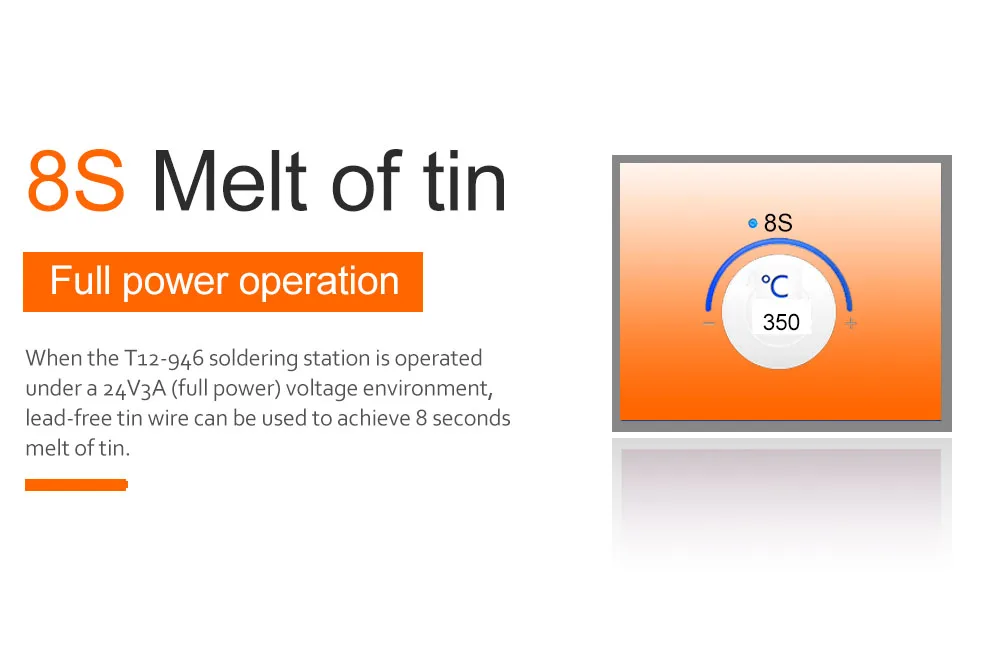

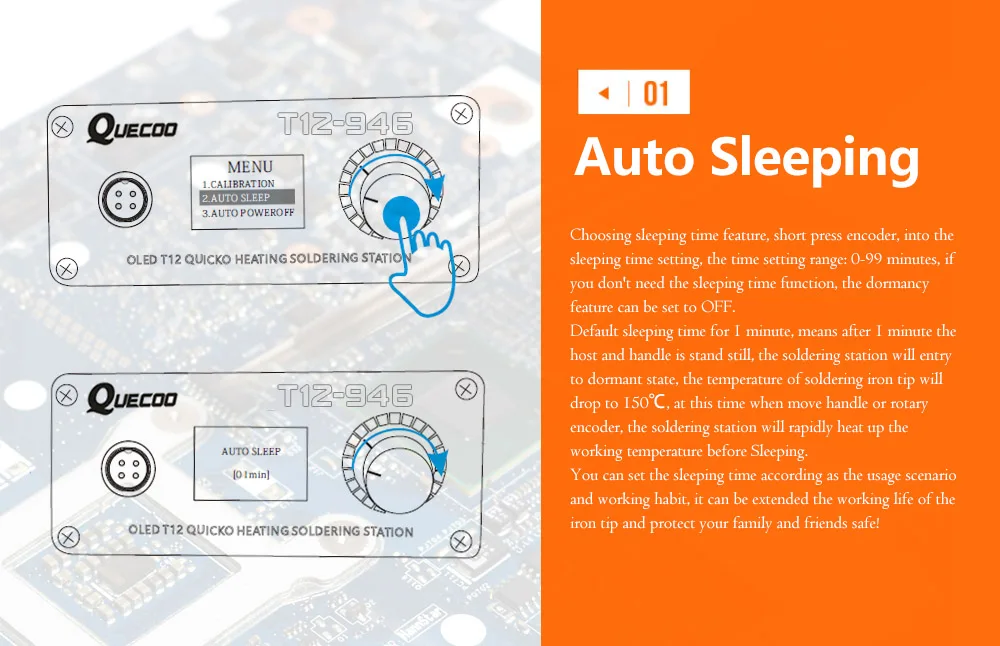

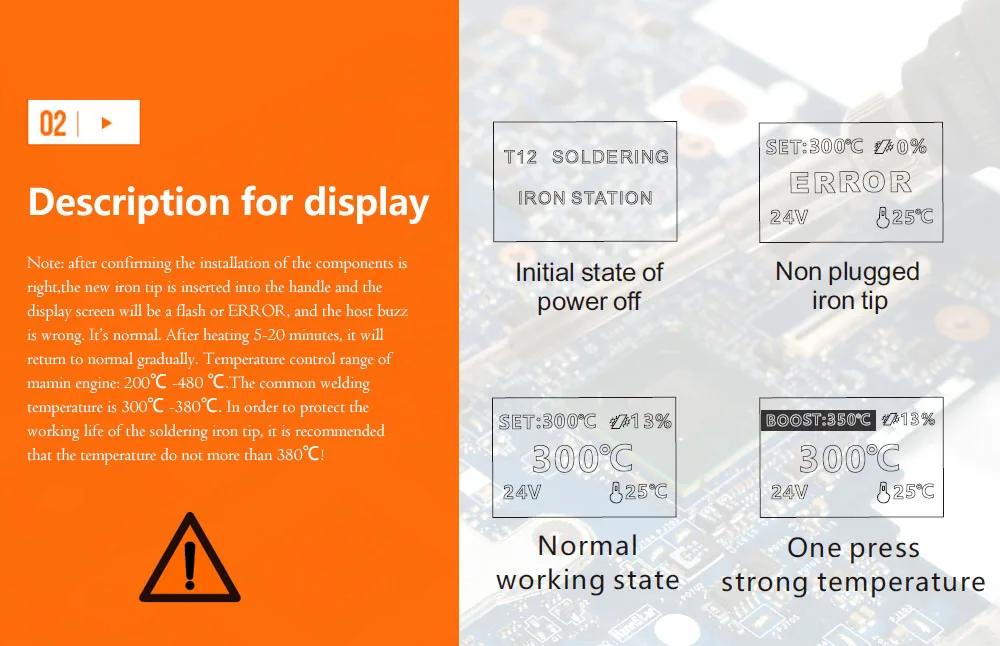

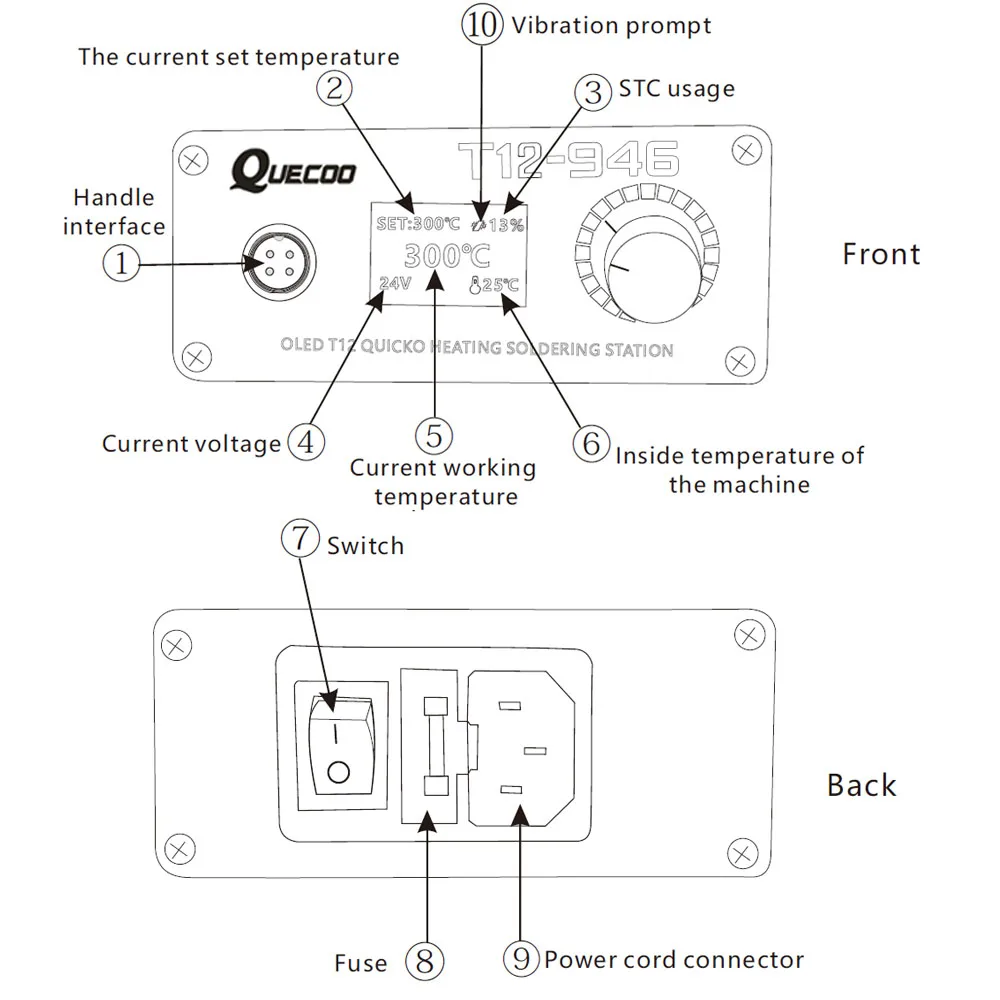

Quick Heating STC T12-946 Mini soldering station electronic 1.3-inch Digital controller with 907 plastic handle welding iron tips NOTE: THIS IS T12-946 MINI Portable OLED T12 solder iron station, doesn't include power supply, You need to buy a DC 24V 4A power supply in addition. Please use a 3-5A power supply to drive this soldering station also. If you want change the default Tip , please tell us or leave a message. The iron tip does not work continuously at high temperatures; high temperatures can easily damage the tip! Ordinary solder melting point is 183 degrees, lead-free solder melting point is 227 degrees, usually the welding temperature is 300-380degC, 380 degrees is the temperature of the dividing line, higher than 380 degrees, iron head oxidation and loss is extremely fast, seriously affect the heating core life The Higher than 380 degrees temperature display will be beating, the higher the temperature, the greater the beating! Recommended in the 300-380 degrees for welding work, most of the work can be carried out, the temperature beating is normal, and it does not affect the use! If you can use low temperature, then do not use high temperature: T12 is constant temperature control, the general recommended working temperature control is between 300 ℃ ~ 380 ℃, higher than 380 ℃ damages the coating ofthe solder tip and cut down the PTC life!

FAQ: 1. Why is the temperature of the new T12 solder tip jumping? Because the inside heating core of the new T12 solder tip did not go through the high temperature, the first time you use it will be a bit warm. Generally, without special treatment, the normal use of 1-2 days after the basic will not bounce. Such as the need to immediately be effective, the general proposal to adjust the temperature to 380- -400 degrees, side of the solder tip to the tip of the tin, burning for 5-10 minutes after the shutdown, until the solder tip cools and then reboot! (If 1 time no effect the first time, then it can be repeated 2-3 times). T12 is pulsating temperature warming; even if the display temperature is flashing, the tip of the real temperature is completely stable. T12 jump temperature is also connected with the temperature control board of procedures, the power of electrostatic and if it connects to the ground. 2. What is the problem of attention when we use the T12 for the first time? T12 tip heating speed is very fast, when the new solder tip connects the electricity, it must be input immediately to the solder tip, for protection, due to heating up fast, just need 6-10 seconds, no time for preparation. so the important is prepare the items which will be welded, and finally boot power, and each welding gap or the end, should be more on the tin to protect and then shutdown, so it can avoid to tin the new sold tip is difficult, especially the T12 tip type of iron, such as T12-I / T12-IL / T12-BL / T12-ILS and so on! 3. What are the precautions for using the T12 tip? a. If can use low temperature, then do not use high temperature: T12 is constant temperature control, the general recommended working temperature control is between 300 degrees and 380 degrees, higher than 380 degrees damages the coating of the solder tip and cuts down the PTC life! b. Do not dry: the first time to use the solder tip, it should be wrapped while heating a layer of tin. If it's without work, shut down immediately! c. Diligent to clean: before shutting down, use a wet sponge or detergent to remove the oxidation of debris, on the tin after the shutdown, power off! d. Standard operation: Do not violent collision the solder tip, do not stamp the top of the hard objects, but can not be used to hot plastic and other materials, specifically reminded that friends like tin should avoid the iron and other hard metal knock tin, the heating core of T12 is in the head of the solder tip, often percussion is a fatal damage to T12! e. Less use of scaling powder: scaling powder can not be used, or can be used as little as possible! When scaling powder helps make beautiful and reliable welding at the same time, but also greatly speeds up the consumption of the coating of the solder tip, T12 heating core high temperature position is very near the Nozzle tip of the solder tip, Scaling powder in the fear of threat to T12 head pressing parts. |

Login to your account. Do n’t have account? Login

Login to your account. Do not have account? Sign up